Wechat/Whatsapp:

+8618825874379

Wechat/Whatsapp:

+8618825874379

HYWATER Reverse Osmosis plant/system

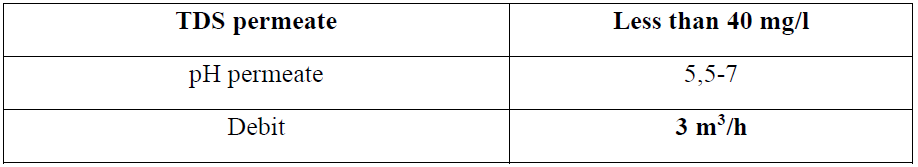

water Treatment unit by reverse osmosis with a capacity of 3 m 3/h What are the conditions that Tunisia needs before installing water treatment equipment? Then I will sort it out for you with the case of our company: Supply of a water treatment unit deep drilling. That unit must be composed by:Raw drilling water has a high iron content and high turbidity, so in order to prevent the formation of iron carbonate and to ensure optimum equipment durability, pre-treatment of the raw feed water is essential to remove deposits and reduce fouling. available power supply guarantees a voltage of 220V / 380V with a frequency of 50 Hz . Site condition: Raw water quality : A-Pretreatment station : An iron and manganese abatement system: This system must ensure that the iron and manganese content is reduced to values acceptable to the membranes of the new reverse osmosis plant. The iron removal and demanganization operations must be carried out separately (in cascade). And all the necessary equipment must be provided to perform the two operations separately such as: - An air injection kit for oxidation and an electric dosing pump with agitator tank for demanganization. - HD polyamide tanks with epoxy treatment inside. - Cartridge filters, sand filters, multimedia filters .... - Automatic counter-current washing machines with the possibility of manual of the washing. - Control panels (including pilot solenoid valves, pneumatic valves for washing, control manometers, etc). A coagulant-flocculant injection system (2x100%): The injection of these agents will be controlled by the water flow at the outlet of the pumps. The dosing system is complete with the necessary accessories for the correct functioning of the operation (bottom valve, level probe, injection valves etc) . A chlorine injection system to fight against biofouling: The chlorine dosage must be precise to avoid oxidation of the membrane material even after dechlorination. Connection accessories and valves: Such as: pressure and temperature measurement and analysis sampling. picture reference: B-Reverse osmosis desalination station: A chemical injection stage (dechlorination / anti-scalant / pH adjustment): This injection stage will be mounted on a stainless steel frame and will be composed of three (03) electromechanical diaphragm dosing pumps, equipped with precise flow control.A tank with a storage capacity of at least 100 L with its agitator will be associated with each pump (03 tanks in total). The water will go through three chemical injection operations which are : - Upstream of the 5 micron filter door, sodium metabisulfite will be injected to perform dechlorination. - The injection of an anti-scalant product downstream of the 1 micron filter gate to avoid the precipitation of iron oxides and the calcification of osmotic membranes. - The injection of liquid soda concentrated at 10% so that the water mixture is balanced (neither corrosive nor incrusting). This injection will be done in a mixing chamber in which a pH probe will be placed. More inquiries related to Water treatment please contact: Mob& Wechat& WhatsApp: (+86)13532836525 Email: sales007@water-sy.com Connect:Eva huang

A pumping skid (2x100%): A two-pump skid will be provided (one pump on, the other in standby mode).The pumps will be selected based on the aggressiveness of the water after aeration.