Wechat/Whatsapp:

+8618825874379

Wechat/Whatsapp:

+8618825874379

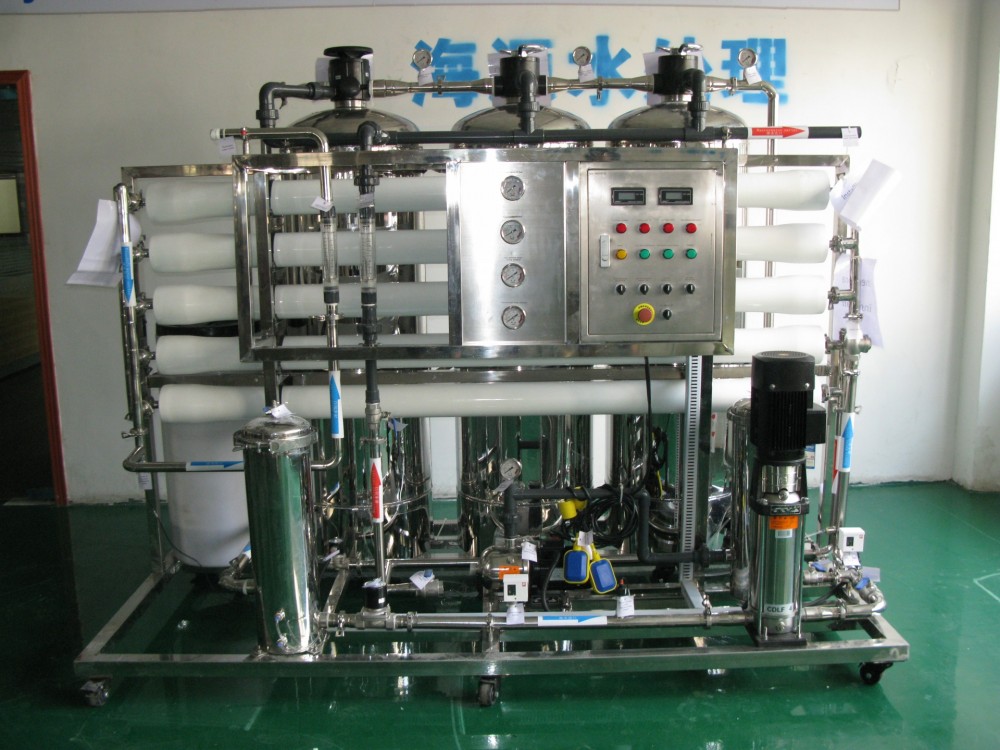

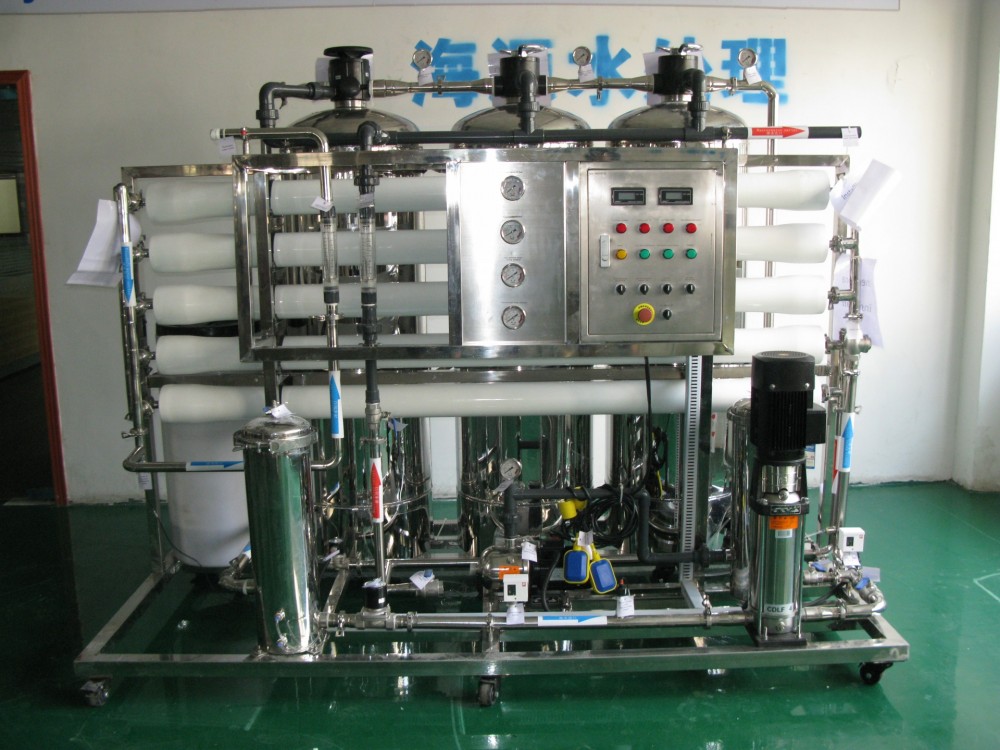

HYWATER Deionized Water System

RO Machine Maintenance Manual I. Low Permeate Flow and High Pressure This situation may be brought about by the following causes: (1) RO machine Deviation in Readings of Instrument and Meter The pressure gauge or flow meter not calibrated prior to use may bring about inaccurate readings. The pressure gauge is mounted at the position far away from the ends of pressure vessel, and its reading contains the pressure loss within piping. If said reading is used as the pressure of feed water, it will be caused that the feed water pressure is inadequate and the permeate flow is relatively low. (2) RO machine Temperature The feed water temperature is lower than the initially designed value. In each temperature drop of feed water by 3℃, the permeate flow can decrease by approximately 10%. (3) RO machine Feed water Conductivity (or TDS) The feed water conductivity (or TDS) is much higher than designed value. For NaCl solution, if the TDS increases by 1000ppm, then the osmotic pressure increases by around 11.4psi (0.8bar), which means that the permeate flow will decrease under same pressure of feed water. (4) RO machine Pressure at Product Water Side Under same feed water pressure, since pressure suppression is set at the product water side or the product water pipe is relatively small while the destination is far away and is at a high position, an obstacle is formed, resulting in the drop of net pressure and decrease of permeate flow. (5) RO machine Pressure Difference Under regular circumstance, for the RO system with each housing containing 6 pieces of 8040-sized elements, the pressure difference between two stages is 3~4 bar. The improper design of piping which may cause considerable pressure loss or the incomplete closing of concentrate discharging valve in the second stage may result in the decrease of loss, thus causing the decrease of permeate flow. (6) RO machine Flux Attenuation of Membrane Element The wet-type membrane element not preserved properly or not protected properly after being installed in the system can become dry, resulting in the drastic attenuation or even complete losing of permeate flow and thus causing the lower water yield of the system. Before the membrane elements are installed in the system, the feed water hasn’t been confirmed to be acceptable, and the feed water used for soaking and flushing the membrane elements may contain cation, neutral or amphoteric surfactant or other chemicals incompatible with membrane, thus causing the attenuation of flux of membrane element and then resulting in the low permeate flow of system More questions regarding the RO machine, please feel free to contact us: Whatsapp/Wechat/Call me via +86 13544774483 Email: sales010@water-sy.com