Wechat/Whatsapp:

+8618825874379

Wechat/Whatsapp:

+8618825874379

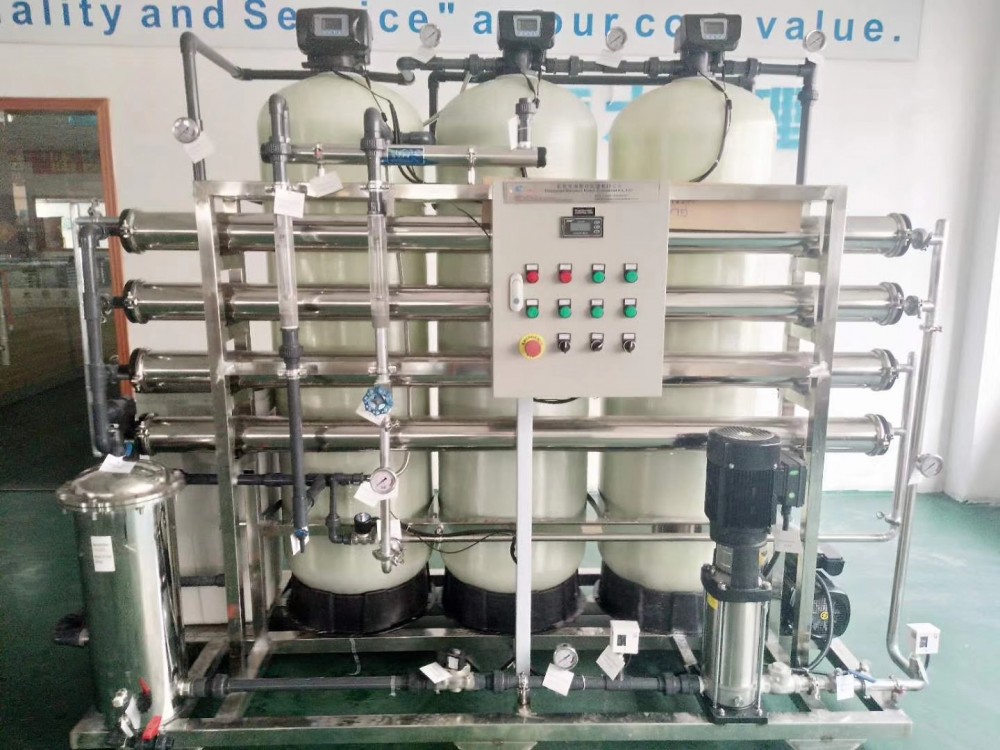

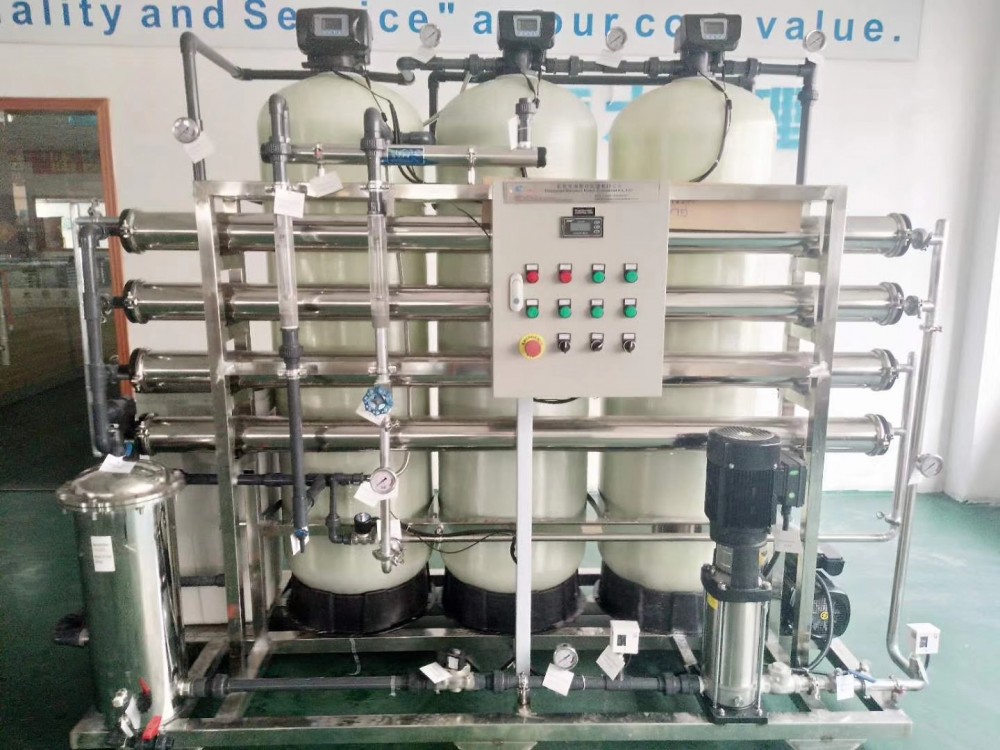

HYWATER Deionized Water System

Industrial Reverse Osmosis System Maintenance Manual IV. Decrease in Permeate Flow after Regular Running In case the permeate flow of RO system decreases after standardization, the cause of failure can be sought according to the following situations: 1. If the decrease of permeate flow occurs in the first stage of RO system, it means there is deposition of granular contaminants. 2. If the decrease of permeate flow occurs in the last stage of RO system, it means that there exists contamination of scaling. 3. If the decrease occurs in all stages of the RO system, it means there exists fouling. A. Determine the cause of failure based upon the symptom and exact position of failure, take corrective measures accordingly, and clean the system in line with Guide to Cleaning of RO System. B. In addition, the decrease in permeate flow of RO system is always accompanied by such situations as the decrease or increase of rejection rate, etc. 4. Decrease in both Permeate Flow and Rejection Rate after Standardization, the decrease in both permeate flow and rejection rate after standardization is the system failure most frequently seen, and is possibly caused by the following: A. Colloidal Fouling,the causes of colloidal fouling: 1) Insufficient amount of flocculant is dosed in the pretreatment process, the jar test hasn’t been carried out for determining the optimum dosage, and on-line flocculation hasn’t achieved a satisfactory result. 2) The multi-media filtration and activated carbon filtration have been overloaded, and the designed velocity of filtration flow is a little higher than necessary, and the system is not backwashed and flushed in time. The designed pore diameter of microfiltration or ultrafiltration membrane is a little larger than necessary. 3) The SDI and turbidity values are not monitored during regular routine operation and management owing to that sufficient importance has not been attached. 5. In order to identify the colloidal fouling, it is necessary to: A. Measure the SDI of raw water B. Analyze the retained substances on the surface of membrane for SDI test. C. Inspect and analyze the sediments on the end surface of the first membrane element in the first stage. 6. Fouling by Metallic Oxides, the fouling by metallic oxides mainly occurs in the first stage, usually caused by the following reasons: A. The feed water contains such ions as iron, manganese and aluminum, etc. B. The feed water contains H2S and air enters the system, thus generating the sulphide salt. C. The fouling is formed by the erosive products from the pipe, pressure vessel, etc. 7. Following are the methods for identifying the metallic oxides: A. Observe the contaminants retained inside the safety filter, and also observe the end surface of the first membrane element and the internal wall of pressure vessel. B. Take out the first membrane element, and dissect it to analyze the composition of metallic ions on the membrane surface. 8. Scaling A. Scaling is formed by the slightly or hardly soluble salts depositing on the membrane surface, and generally takes place in the brackish water system that operates under high hardness and alkalinity of raw water and requires high recovery rate. B. It occurs especially in the last stage of RO system, and gradually spreads toward the preceding stages. C. Scaling may possibly occurs in those raw water containing calcium, bicarbonate radical or sulfate radical within several hours of running, which can block the RO system. Other scaling may be formed slowly. D. Following situations can cause the fouling: 1) The quality of raw water has not been analyzed, and insufficient amount of antiscalant has been dosed or the antiscalant has inferior effect. 2) The raw water has high hardness and the recovery rate is excessively high, therefore the precipitation and separation cannot be inhibited by simply dosing the antiscalant. 9. The method to identify whether scaling occurs: A. Check the concentrate side of system to make sure whether scaling is formed, which may cause the roughness feeling of internal wall and end plate of pressure vessel. B. Take out a membrane element from the system and measure its weight. The membrane element with serious scaling generally has a heavy weight. C. Analyze the quality data of raw water. 10. Decrease in Permeate Flow and Increase in Rejection Rate after Standardization This failure is possibly caused by the following reasons: A. Densification of Membrane If the membrane is densified, it will usually come into being that the permeate flow decreases and the rejection rate increases. The densification of membrane will likely occur in the following situations: 1) The pressure of feedwater is excessively high pressure and exceeds the permitted limit. 2) The feedwater is at a relatively high temperature and there is serious phenomenon of water hammer, in which case the instantaneous pressure exceeds the permitted limit. The method to identify the densification of membrane: Take out a membrane element and dissect it. Take out a piece of membrane for analysis of its microstructure. 11. Contamination by Organic Substances The organic substances contained in the feedwater can be adsorbed to the surface of membrane element and result in loss of permeate flow, which occurs generally at the first stage. The reasons causing organic contamination are basically similar to the ones causing the colloidal contamination. Following are the methods for identifying the contamination caused by organic substances: A. Analyze the retained substances on the filtering element of safety filter. B. Inspect the flocculant for pretreatment, especially the cation polymer. C. Analyze the oil and organic contaminants in feedwater. D. Inspect the detergent and the surfactant. More questions regarding the RO System, please feel free to contact us: Whatsapp/Wechat/Call me via +86 13544774483 Email: sales010@water-sy.com