Wechat/Whatsapp:

+8618825874379

Wechat/Whatsapp:

+8618825874379

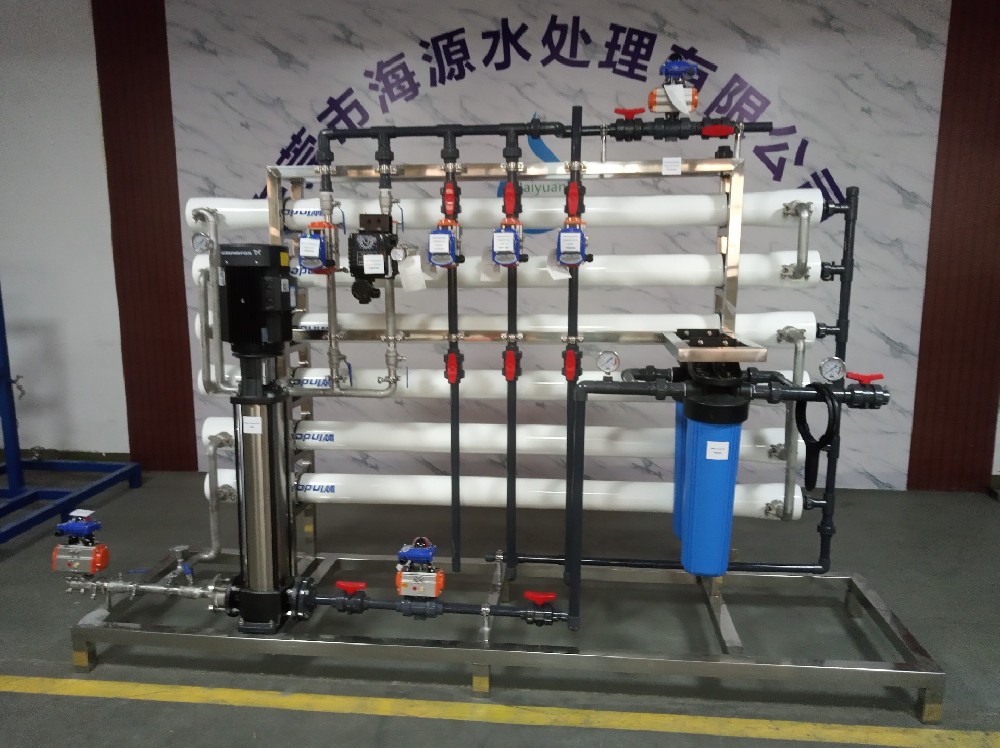

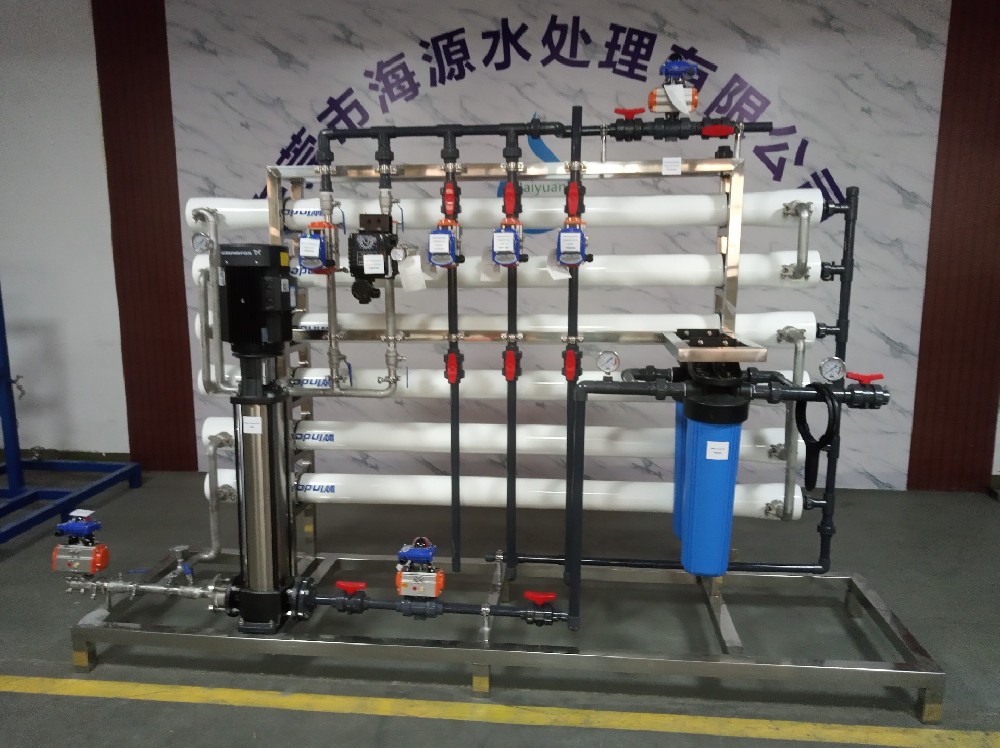

HYWATER Reverse Osmosis plant/system

About Back pressure of Reverse osmosis system In the field of reverse osmosis system, back pressure refers to the situation where the pressure on the product water side is greater than the pressure on the feed water side. The coiled membrane element is similar to a long envelope-shaped membrane bag, and the open side is bonded to the product water center tube containing the opening. Wrap multiple membrane pockets on the same product center, so that the water supply flow flows through the outside of the membrane, and under the pressure of the water supply, the fresh water enters the membrane pocket through the membrane and then flows into the central pipe of the product water. In order to facilitate the flow of product water in the film bag, a layer of fabric support layer for product water diversion is sandwiched in the envelope-shaped film bag; The water supply channels between are sandwiched with a mesh layer. The three sides of the membrane pocket are bonded together with adhesive, if the pressure on the product water side is greater than the pressure on the feed water side, then these bonding lines will break and cause the loss or obvious reduction of the desalination rate of the membrane element, so from the perspective of safety From the point of view, the reverse osmosis system cannot have back pressure. Since reverse osmosis membrane filtration is driven by pressure, there will be no back pressure during normal operation, but if the system is normal or malfunctions, or the valve is set or opened and closed improperly, there may be back pressure, so it must be properly handled Solve the problem of back pressure. Generally, technical manuals related to reverse osmosis membranes have back pressure limit parameters. It is assumed that the maximum back pressure that the reverse osmosis membrane can withstand is 0.1 MPa, which is about 1 bar, which is about equal to the pressure generated by 10 meters of water column. When the reverse osmosis is shut down, the water in the water production pipe will inevitably generate a certain pressure on the water production side of the reverse osmosis membrane, and the higher the water production pipe climbs, the greater the pressure will be. If the water production pipe climbs over 10 meters, then The back pressure of the product water on the permeate side is enough to cause membrane damage. Therefore, in the reverse osmosis design process, 8 meters should be specified as the maximum climbing height of the water production pipe, and a check valve should be installed on the water production pipe to prevent the water in the water production pipe from generating pressure. Sometimes it may happen that the check valve is not tight or the climbing height of the water production pipe must be increased. In this case, the method of installing an emptying pipe after the check valve of the water production pipe can be adopted to prevent back pressure. . Another type of back pressure is caused by operator error. During the operation of reverse osmosis system, if the operation is wrong. Turning on the water pump when neither the product water valve nor the product water discharge valve is opened will cause the system pressure to rise continuously and the pressure on the product water side to continue to increase but no water will be produced. The water production pipeline is generally made of UPVC material. If the pressure is too high, once the pipeline bursts, it may cause a safety accident. At this time, if the operator urgently opens the production valve to release the pressure, the accident can be avoided. However, if the operator takes the method of stopping the water pump, the pressure on the water inlet side will suddenly drop, and the pressure on the product water side will be very high. Such a high back pressure will immediately cause damage to the membrane. Therefore, designers should also take this into consideration during the design process. A bypass can be installed beside the production and discharge valve, and a bursting disc can be installed on the bypass. Assume that the bursting pressure of the bursting disc is 0.3MPa. When the water side pressure exceeds 0.3MPa, it will automatically explode and release pressure to prevent greater losses. In addition, due to the irregularity of the bursting membrane, the bursting membrane explodes randomly when the blasting pressure is not reached, or the bursting pressure does not explode. Sometimes, in order to save trouble, the on-site personnel directly replace the bursting membrane with an iron plate or other materials. It's really irreversible. Therefore, we must follow the specifications and do a good job in the bursting membrane experiment. On-site commissioning personnel of reverse osmosis system should also pay attention. During the operation of the reverse osmosis system, remember to check whether the water production valve and the production and discharge valve are open before starting up, and open the production and discharge valve first before shutting down to prevent back pressure accidents. . More inquiries related to Reverse osmosis system please contact: Mob& Wechat& WhatsApp: (+86)13544774483 Email: sales010@water-sy.com We will provide high-quality, all-round comprehensive professional services for project consulting, system design, manufacturing, installation and commissioning, personnel training, etc