Wechat/Whatsapp:

+8618825874379

Wechat/Whatsapp:

+8618825874379

HYWATER Reverse Osmosis plant/system

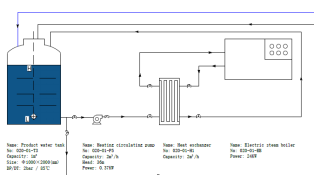

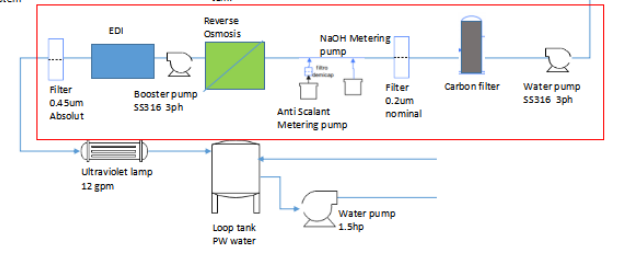

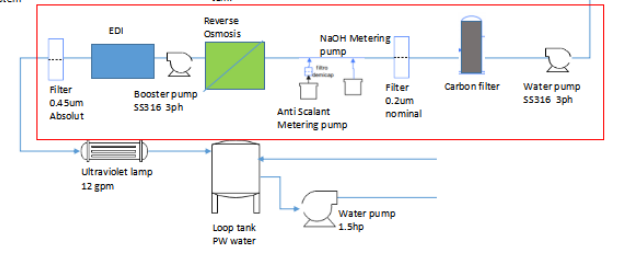

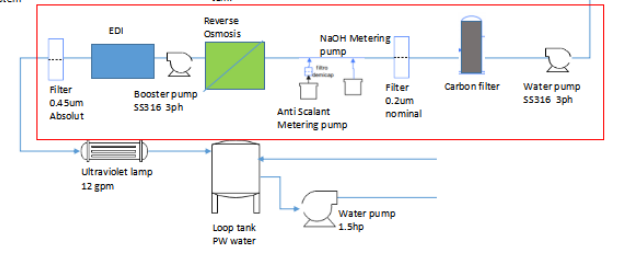

500LPH one pass RO and EDI system for PW water 1.500LPH reverse osmosis system for Pharmaceutical water Project description Recently, I would like to share a pharmaceutical water solution we designed for a client in El Salvador. This client comes from a pharmaceutical company, so the requirements for the produced water are relatively strict, and it needs to meet the GMP pharmaceutical water standard: TOC less than 500ppb, PH 5-7,Conductivity for PW less than 1.3 us/cm In order to make thae suitable proposal for the 2GPM Pharmaceutical water treatment system,The client has taken the source water( municipal water) sample to get a water quality report, and water quality parameters as below: Free Chlorine: 2.0 ppm PH: 6.7 Calcium: 46 ppm Magnesium: 26 ppm Manganesum: 0.07 ppm Alkalinity Carbonates: 0.4 ppm Conductivity: 802 micro siemens Nitrates: 31 ppm Barium: 0.035 ppm Sodium: 54.6 ppm Fluor: 0.65 ppm TDS: 395 ppm Sulfates: 60.9 ppm Turbidity: 0.1 NTU Iron: 0.04 ppm Silica: 95 ppm Chlorides: 54 ppm Potasium: 10.7 ppm Alkalinity bicarbonates: 239.5 ppm 2.500LPH one pass Reverse osmosis and EDI system for PW water Q&A Between Us Client: the system should be made of Stainless Steel or other sanitary approved plastic that could support hot water sanitization (80 Celsius for 30 minutes, every week) Reply:Generally,the plastic pipes are not suitable for high temperature disinfection at 80℃,So we recommend stainless steel. Do you have any preference for stainless steel? We usually choose SUS304 or SUS316 for pharmaceutical water treatment plant. Client:Yes. Go with SUS 316 Reply:if the whole system materials are all made of SUS316, the price is relatively expensive, so we recommend SUS304 for the pretreatment and RO parts and SUS316 for EDI part,do you think this way is okay? Client:Ok. It sounds good to me Please remember that we want to pass the hot water through the RO and EDI to keep them sanitized Reply:Well,the RO and EDI parts can be sanitized by passing 80℃ hot water,We will choose components that can withstand high temperatures of 80 degrees Celsius for you. Client:Ok,pefect. Reply:Does the pretreatment part also need to be sterilized by 80 degrees Celsius hot water? Client:Will the valves resist the hot water? Reply:if need prefilter also need hot water.we will change statinless steel valve. Client:We will need only the carbon tank,The sand filter and softener will be located before your system. Reply:Okay,so we’ll only provide you a carbon filter with statinless steel valve. And this is the basic process flow we designed according to your requirements. Feed water pump---Active carbon filter---Security filter---High pressure pump--- RO system ---RO product water tank---EDI booster pump ---EDI system Client:Can you avoid the RO water tank? Reply:We add the RO product water tank so that the EDI system can still pump water from the RO water tank for work when the RO system is being maintained. Client:RO almost no need maintenance Reply:Good,then we can not add ro water tank based on ur requirment. Client:Do you include an automatic flush cleaning in RO?How do you flush automatic the RO with chemicals? Reply:Yes,The PLC has a key button function, but it needs to prepare the chemical cleaning agent manually in advance. Client:That’s enough. We will use softened and filtered water to feed RO. And, also, NaOH injection and Anti Scalant injection.Please include these chemical metering pumps Reply:Ok,no problem Client:Remember the hot water sanitizacion in your system. Two times a week Reply: Got it.this is our hot water sanitizacion system process flow then need we supply the loop pipes,bends and valves? Client:The loop already exists,Just to know what do you do to avoid bacterial growth during off times: nights, weekends, etc? Reply: there are loop system,and entire system also can hot water disification. 3.The pictures of similar 500LPH one pass RO and EDI system for PW water 4 Similar process flow chart for 500LPH one pass RO and EDI system for PW water More about RO and EDI system for PW water details: Contact us: Email: sales005@water-sy.com Wechat and Whatsapp: +86 135 3852 3642