Wechat/Whatsapp:

+8618825874379

Wechat/Whatsapp:

+8618825874379

HYWATER Reverse Osmosis plant/system

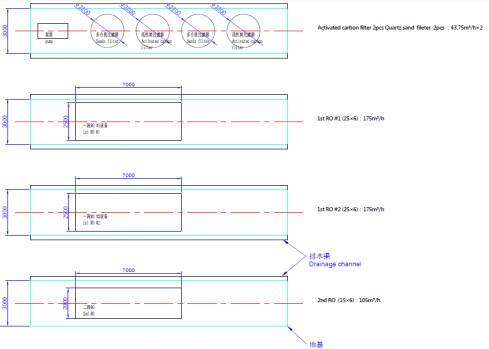

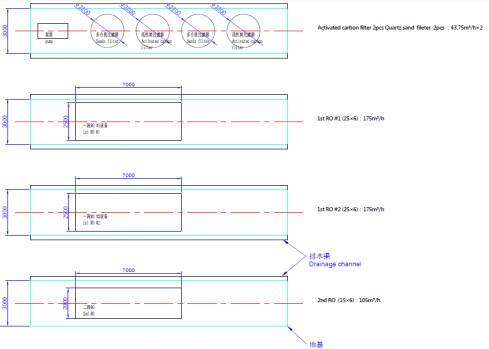

350m3/hour project Industrial effluent water after the cooling of reactors Haiyuan water treatment team supply pharmaceutical waste water deep treatment solution for Belarus. Please check below client met question and we solution for 350m3/hour big project. Here are the details of our discussion with customers:Regarding the 350m3/hour project. At the moment the design of the sewage treatment plant of the metallurgical plant is in progress. Industrial effluent is water after the cooling of reactors and is not highly contaminated: Parameter Before request After request Remark Suspendedproducts 47 mg/ 20-30 mg/l Petroleum products 17 mg/l 3 mg/l Salinity 17 mg/l 1300 mg/l Total iron 0,34 mg/L 0,34 mg/L Total hardness 27,3 mg 2,0-2,5 mg Chlorides 1093 mg/L 250 mg/L Sulfates 442 mg/l 350 mg/l COD mgO2/dm3 15-20 mg/l BOD 136 mgO2/l 15-20 mg/l. The first stage we plan to put a drum sieve to delay mechanical impurities, and then flotation units (they will significantly reduce the content of suspended solids, petroleum products, COD, BOD, but will add some chlorides/sulfates, depending on the coagulant used). Approximately after flotation, the content of suspended solids will not exceed 15-20 mg/l, petroleum products less than 1 mg/l, COD, BOD by our experience after flotation are reduced by 5-10 times. Taking into account the fact that it is necessary to reduce salt content - practically the only option we see RO. However, COD, BOD and suspended solids content after flotation is higher than it is necessary for correct operation of RO, so we consider it necessary to put filtering columns with sand, coal and ion-exchange resin. Since you have a lot of experience with RO equipment and filter columns, please guide us. Regarding evaporation, reverse osmosis produces about 10-15% of the total salt concentrate water. We are laying with the reserve - about 45m3 / hr. However, as already mentioned earlier - you have Then our engineers provide customers with the following process flow chart: Feed water tank----Feed pump----Quartz sand filter----Activated carbon filter (with backwash pump)----precision filter----pretreatment water tank----1 stage RO booster pump----scale prevention device----precision filter----1 stage high pressure pump----1 stage RO system (CIP)----product water tank (1 section of concentrated water tank)1 stage concentrated water tank----2 stage high pressure pump----2 stage RO system----product water tank. reverse osmosis water purification machine approximate dimensions of the installations: Confirm membrane with belarus client: Could you please guide me on the number of membranes? I don't quite understand the number of reverse osmosis membranes. The single group reverse osmosis system is 150 pieces, below it says in the spec 8040 membrane x6 - 50 pieces (that's just 300). The quantity on the side is listed as 300 and below is 25*6 (so 150?). Does that turn out to be 300+150 or am I misunderstanding? I am find 350m ³ the same picture as the project and point with red typeface , i think this is can help you Because 1-stage RO, it is need 5pcs*5pcs*6pcs(membrane)=150, this is need 2 group so that is 150*2=300pcs(membrance) And 2-stage Ro , it is need need 5pcs*3pcs*6pcs(membrane)=90, this is need 1 group so that is 90pcs(membrance). In the end, they were praised by customers: Connect: More Industrial effluent water after the cooling of reactors info pls contact us:Email:sales007@water-sy.com Web: www.seawaterroplants.com Mobile/Whatsapp/Wechat +86 13532836525